Benefits of SOLIDWORKS in Process Design

- Design of Dies and Tool Sets for Plastic/ Sheet-metal/ Casting/ Forging Components

- Integrated FEA for Tool Stress Analysis

- Tolerance Analysis in 3D

- Ability to work with multiple 3D CAD data – Pro/Engineer, CATIA, Unigraphics, IDEAS among others

- Production-ready Bi-Directinal Parametric 2D Drawings that update automatically with Design Changes

- Communicate 2D and 3D Designs using e-Drawings – for SOLIDWORKS, DWG and DXF

- Customized Menu Interface for Mould and Tool Die Designs

- Reduce or eliminate ECO’s and ECN’s ( resulting in cost benefits )

- Surface Quality Checks – Design For Manufacture Tools

Special Toolset for Equipment Design

Business Benefits for companies using AutoCAD

- Safe re-use of existing legacy 2D CAD Data – No need to spend money in data conversion

- No further investment in 2D CAD – No need to upgrade AutoCAD

- e-Drawing – Free Viewer for DWG & DXF Files – Saves Money across the Company

- 3-user license of DWGEditor for every license of SOLIDWORKS on Subscription – Protects investment in 2D & 3D CAD

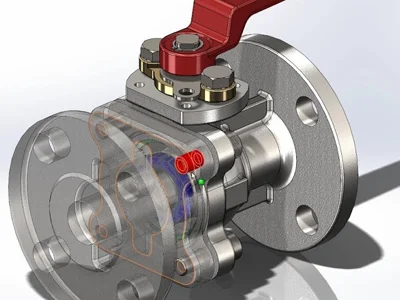

- Perform Design Validation using Cosmos FloWorks & FEA at concept stage – Saves Time, Effort and Money

- More Designs in Less Time – Increases Design Efficiency by Up-Front Engineering Simulation

- Enhance Process Equipment Reliability

- Market YOUR Product Designs more effectively using e-Drawings

- Customize designs using Superior API functionality – Drawing Automation reduces Time and Cost of development

Why BUY SOLIDWORKS, for Process Equipment Design, from EGS India, Chennai / Coimbatore?

- Technical support from product design engineering team with in-depth experience in handling large design projects, since 1993

- SOLIDWORKS Authorized Testing, and Training Centre

- Proven Experience in Design Simulation – RLA & Solution for Failure Modes

- Imparting innovative design processes and best practices to accelerate product development

- Specialists in Large Assembly Management, Design Automation using VBA & Drawing Automation